Our Services

Vibration analysis

Vibration analysis is one of the most effective methods to detect problems in machinery both Electrical and Mechanical problems. With vibration analysis we can identify potential problems that can be catastrophic to company operations. We pass this information to the planning team who then plan and schedule corrective measures to be done on the machines. Vibration analysis is applicable to companies that have rotating equipment that are critical in their plant. These machines include motors, gearboxes, compressors, fans, pumps, conveyors, elevators e.t.c. With combination of vibration and shock pulse measurement, we will be able to detect the following faults: Professional Machine Inspectors Ltd uses state-of the-art thermal imagers combined with trained and experienced personnel to carry out infrared analysis on critical plant equipment. This procedure picks out hotspots and faults that could be catastrophic to plant operations or cause expensive breakdowns in the plant.

Thermography

Professional Machine Inspectors Ltd uses state-of-the-art thermal imagers combined with trained and experienced personnel to carry out infrared analysis on critical plant equipment. This procedure picks out hotspots and faults that could be catastrophic to plant operations or cause expensive breakdowns in the plant. Thermography is applicable to electrical panels, electrical components such as transformers, contactors, power distribution boards, switchgears, boilers, substations and even rotating equipment components.

Thermography is applicable to electrical panels, electrical components such as transformers, contactors, power distribution boards, switchgears, boilers, substations and even rotating equipment components.

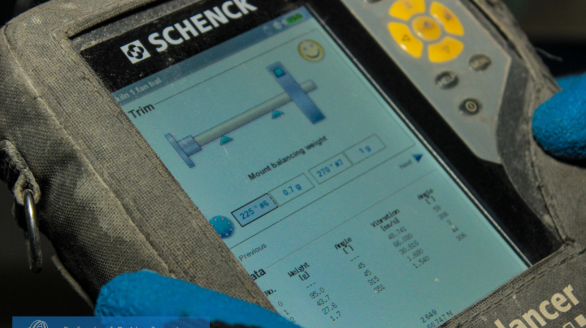

On site dynamic balancing

At PMI we dynamically balance on site and the machine does not have to be taken to a workshop. We do both single and dual plane balancing which is applicable to fans, rotors. Rotating parts such as impellers, rotors can get out of balance by material build up or wear on the rotating part. This will cause excessive vibration and extra loading/strain on components hence the need for our on- site balancing solution.

Precision laser alignment

At PMI we use state-of-the-art laser alignment instrument to give very accurate alignment and thereby reducing maintenance costs and power consumption by up to 17%. We are able to do all types of alignment: Direct Coupling (horizontal and vertical), belt alignment, cardan shaft alignment, machine train alignment. Laser alignment is particularly important after decoupling a machine train or during shut downs.

Trainings

Our training programs are designed to equip maintenance professionals and other personnel in a factory setup with the knowledge and skills needed to effectively monitor, diagnose, and prevent equipment failures through data-driven approaches. We provide comprehensive training modules that cover topics such as, data collection techniques, data analysis, and predictive maintenance strategies. Our commitment to staying up-to-date with the latest industry advancements ensures that our clients receive cutting-edge training, enabling them to implement CBM and Vibration Analysis practices that significantly reduce downtime, extend equipment lifespan, and enhance overall operational performance.

Machine Overhaul

At PMI we overhaul equipment to good condition using the right tools and experienced engineers and technicians adhering to engineering standards. After equipment overhauls, equipment performance is monitored to ensure optimum performance using technologies such as vibration analysis and thermography.

15+

Benefits to Our Clients

By combining our state-of-the-art technologies with highly skilled and internationally certified engineers, your company will benefit in the following ways:

- Eliminate expensive breakdowns of critical machines.

- Reduced maintenance costs by ensuring maintenance is carried out only when required.

- Root cause analysis We fix a machine once, we fix it right!

- Energy savings by ensuring machines are running in good condition

- Priority client for those that have a contract with us